Your depth of knowledge and our breadth of knowledge:

a powerful combination!

With our development and design services, we offer discerning industrial customers a strong partner in challenging times. Our work is based on the expertise and depth of knowledge of our customers. Combined with our breadth of knowledge and experience, we regularly produce innovative and cost-optimised solutions.

IQ was yesterday. Today is WeQ. Utilise this knowledge advantage for your development projects.

- Design and development

- Calculation and simulation

- Technical documentation

The high demands of technological and economic competition are presenting you with new and complex challenges more than ever before. Particularly in mechanical engineering, new solutions are required with increasingly shorter development times.

We put together experienced and expert development teams to meet your requirements. Our fixed price with guaranteed deadlines is also convincing.

Together we develop creative approaches that lay the foundation for innovative solutions.

By intensively collecting ideas, we create an inspiring environment for the development of well elaborate concepts.

Our experts translate your requirements into well elaborate solution concepts that focus on efficiency and practicality.

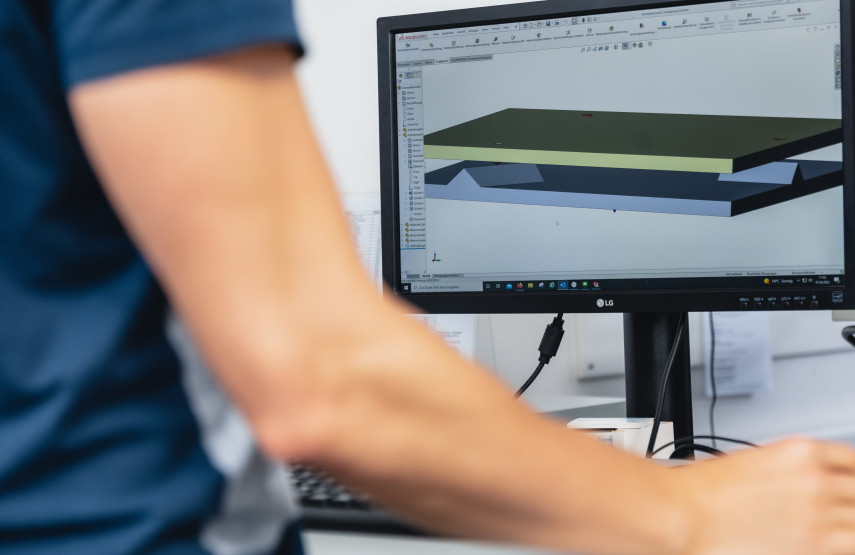

We use state-of-the-art technology to design and visualize your projects with precision and attention to detail.

The total costs of your product can be significantly reduced through various optimization options such as modularization, standardization or material selection.

Comprehensive analyses identify potential for increasing efficiency in your work processes.

Seamless integration of our solutions into your Product Data Management (PDM) ensures a smooth workflow.

From optimization to support during the production phase, we guarantee the highest quality and efficiency.

AutoCAD, Autodesk Inventor, CATIA, Creo Parametric, Creo Elements, Siemens NX, Solid Edge, SolidWorks

However, what is not yet there can already be calculated and simulated. This helps to run through initial assessments, calculations and procedures and to think through different scenarios. What is important here is the open process, which is based on knowledge and supported by the latest technology.

We use FEM to carry out detailed stiffness analyses to ensure the structural integrity of your components.

Our analyses, e.g. in accordance with FKM, GL or Eurocode, ensure that your construction can withstand the loads and meets the highest safety standards.

Precise modal and frequency response analyses optimize the performance and reliability of your systems.

We use advanced simulations to analyze the behavior of complex mechanisms and ensure optimum functionality.

Careful consideration of machine elements such as gearboxes, shafts or gearings ensures robust and efficient designs.

By simulating and analyzing flowing fluids, the design of the surrounding construction can be optimized.

Realistic simulations optimize processes and minimize potential bottlenecks in your production.

Virtual commissioning enables efficient testing and optimization before systems are physically put into operation.

ANSYS Workbench, KissSoft, KissSys, Bearinx, MathCAD, Cymex, MATLAB, Simulink, EPLAN Fluid

Is simply part of it! Preparing information on technical issues, product-specific data or the precise documentation of processes is a quality feature of Roschiwal+Partner. In a structured, precise and comprehensible way, we create technical documentation that brings knowledge together and holds it together.

Especially in technical documentation, we speak the same language.

Your project requirements are defined as well as systematically and precisely translated into successful project results.

Safe products thanks to the conformity assessment procedure in accordance with the Machinery Directive 2006/42/EC and Machinery Regulation 2023/1230.

Through a comprehensive risk assessment, we minimize potential risks in your projects and increase safety.

The FMEA method enables us to thoroughly analyze and evaluate potential sources of error and their effects.

Detailed instructions for operation and installation ensure smooth implementation of your systems.

Professional drawings serve as clear guidelines for the successful implementation of your projects.

Bespoke mechanical engineering

Our design and development services always focus on your individual requirements. The result is always your customised solution. Bring a breadth of knowledge into your team.

Contact usWe also provide support with

Cleaning for cleanroom and

vacuum applications

Software development

Electrical engineering

Switch cabinet construction

(Series) production and

assembly commissioning