Tooling machines

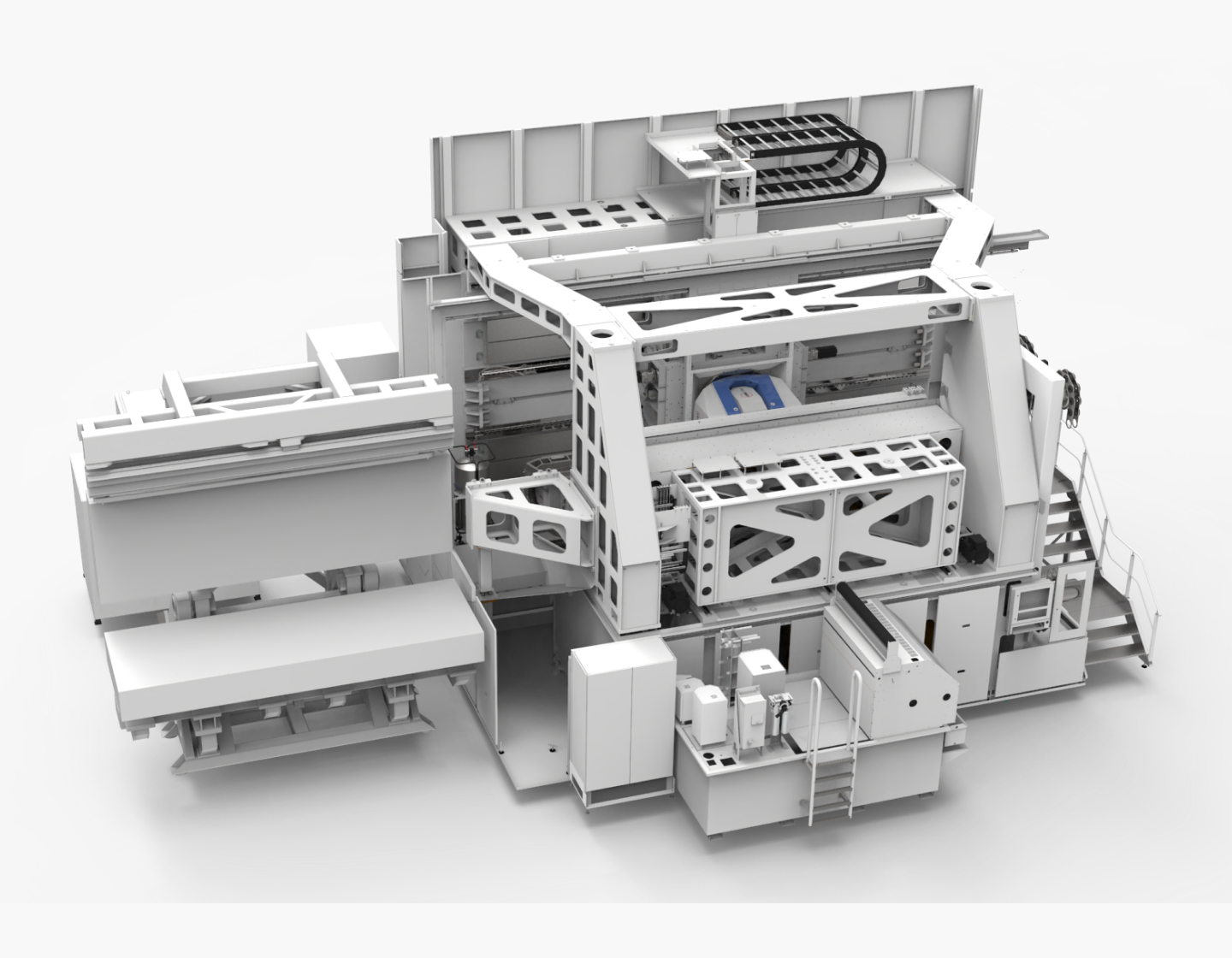

One of our core competencies is tooling machines in production technology. Our extensive knowledge, which we have built up over more than 40 years in the industry, provides you with various solutions to suit your requirements profile. From machining centers for watch parts in the micrometer range to portal milling machines for aircraft structural parts, we feel at home in all dimensions. Our design engineers look forward to your inquiry and will provide you with pragmatic and high-quality support in your process.

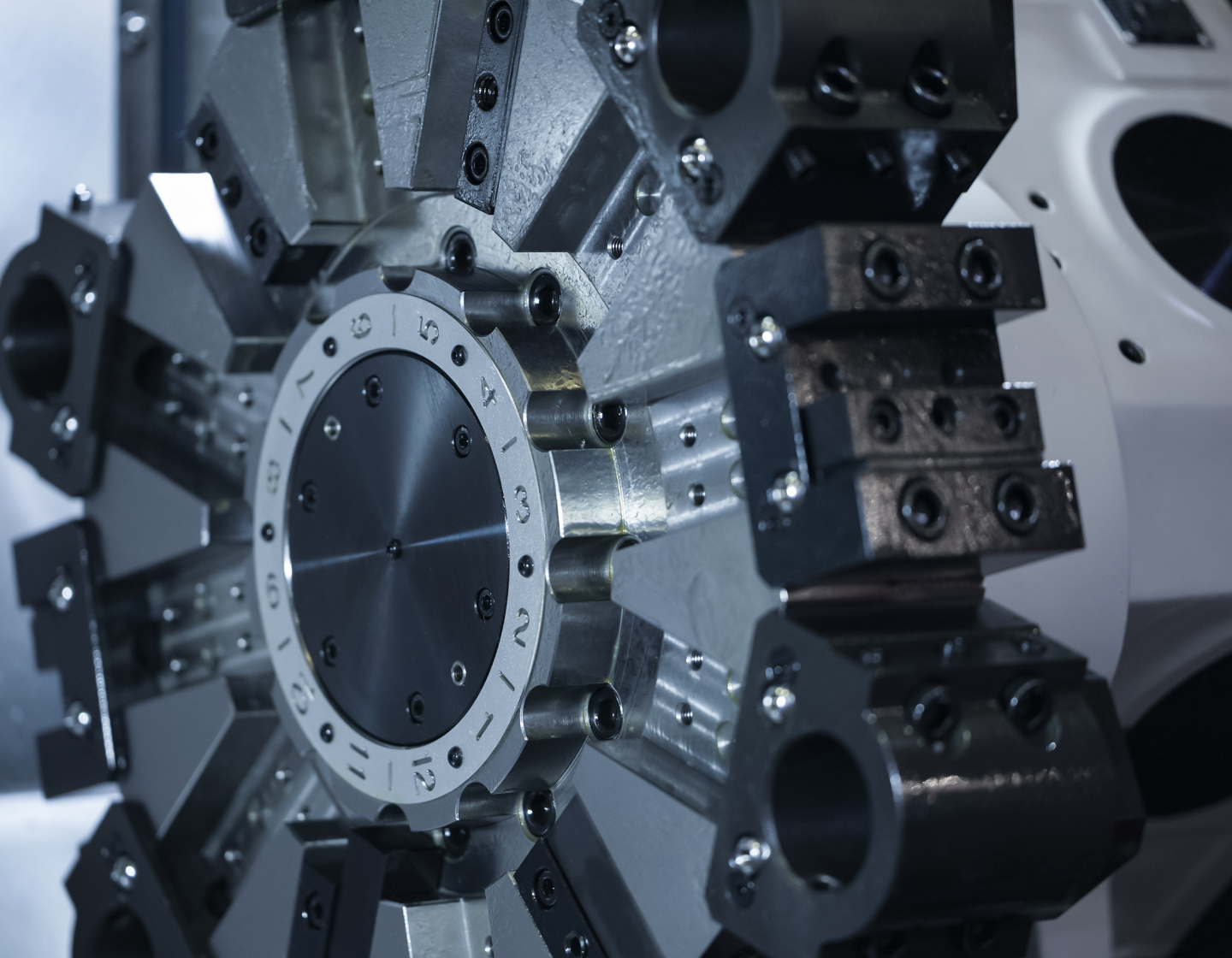

- CNC-controlled 5-axis machine with 42 workpieces, automatic tool change and tool clamping with 110 mm spindle distance

- Machining center for processing wood, aluminium, plastic and composite materials; with 360° swing angle and 600 kg table load

- High-speed milling machine, with spindle speed 30,000 - 100,000 rpm

- Portal milling machine with rotary table Ø 6,500 mm, passage width 8,000 mm, table weight approx. 100 tons

- Hob with automatic loading system, workpiece diameter 300 mm, workpiece weight 30 kg

- Machining center for titanium machining: feed force: 5 tons/axis, installation area 100 sqm, tool holder HSK 125

- Lathe: Turn-mill center for large crankshafts, workpiece weight 50 tons, length 10,000 mm, Ø 1,100 mm

- Surface grinding machine combined with contour grinding for turbine blades

- Circular grinding machine, orbital diameter 280 mm, center distance 1,500 mm

- Tool grinding machine with automatic grinding wheel changer and automatic tool changer